English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  অসমীয়া

অসমীয়া  ଓଡିଆ

ଓଡିଆ  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Why Use Coking Equipment?

-

Why Use Coking Equipment?

-

Deep Dive: Coke Guide & Coal Bunker

-

Technical Specifications of Our Coking Equipment

-

Common Questions & Answers about Coking Equipment

-

Recent Industry News & Summary / Contact

How does coking equipment work?

Coking equipment is designed to carry out coal carbonization (coking) — i.e. heating coal in an oxygen-deficient environment to drive off volatile compounds, leaving solid coke. This process typically involves: preheating, pyrolysis, gas release, controlled cooling, and handling of by-products such as coal gas and tars. The coking equipment provides the mechanical structure, heat management, sealing systems, and material handling required for safe, efficient, and continuous operation.

Why is coking equipment critical in industrial operations?

-

Efficiency & yield control: The right design allows optimization of coke yield and gas/volatile recovery.

-

Process stability & safety: Proper sealing, insulation, and control systems reduce heat loss, manage pressure, and maintain safe operation.

-

Emission control & environmental compliance: Modern coking equipment integrates gas capture, sulfur removal, and dust control systems.

-

Durability & uptime: High-quality materials and design reduce maintenance downtime, prolong life, and ensure steady operation.

What types of coking equipment exist (and what do they do)?

Examples include:

-

By-product coke ovens

-

Non-recovery (heat recovery) coke ovens

-

Fluidized bed coking units

-

Delayed coking (in petroleum refineries, though conceptually related)

Each type addresses different feedstock, scale, byproduct handling, and operational parameters.

Thus, when selecting coking equipment, an industrial buyer must consider feed coal properties, desired throughput, emissions constraints, recovery of byproducts, and integration with downstream processes.

Deep Dive: Coke Guide & Coal Bunker

Coke Guide

Coke Guide, the solid carbon-rich residue from coal carbonization, is a critical input in metallurgical, chemical, and energy applications. Its properties (e.g. strength, porosity, ash, fixed carbon) determine its usefulness in blast furnaces, foundries, gasification, and other systems.

Key points:

-

Porosity & reactivity: Coking creates a porous structure, boosting combustion / reduction behavior.

-

Strength & size: Good coke must resist abrasion and maintain structure under high loads.

-

Gas recovery: The volatile products (coal gas, tar, ammonia, sulfur compounds) are condensed and cleaned for reuse or sale.

-

Integration: Coke often goes into blast furnaces, and gases feed heat systems or chemical plants.

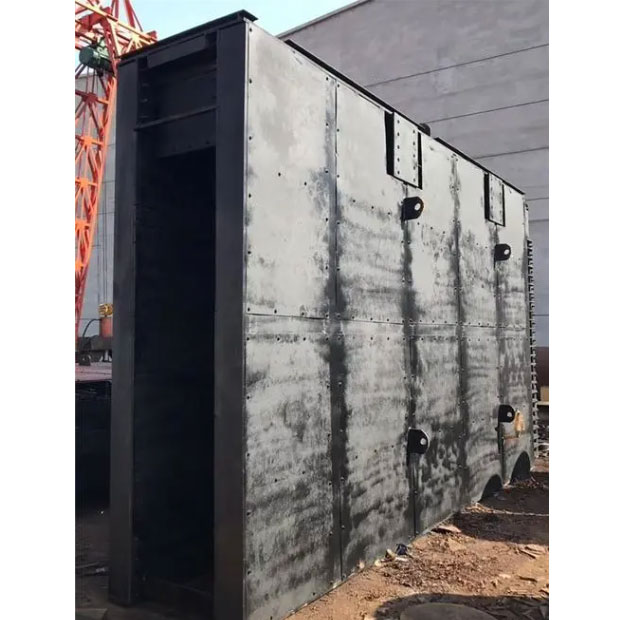

Coal Bunker (its role and design)

A coal bunker is the intermediate storage facility between coal feed systems (crusher / pulverizer / feeder) and the coking equipment. Its design and performance are critical because it buffers fluctuations in feed supply, ensures consistent feed rates, and protects against blockages.

Important design and functional factors:

| Feature | Explanation / Importance |

|---|---|

| Capacity & Volume | Must hold sufficient coal to maintain steady feed during interruptions or maintenance. |

| Feed uniformity | Design to permit uniform flow (avoid bridging, rat-holing) into feeders. |

| Structural strength | Must handle the weight, dynamic loads, and possibly temperature effects. |

| Sealing & inert gas / dust control | Minimizes oxygen ingress, dust emission, and spontaneous combustion risks. |

| Feeding mechanism | Rotary feeders, vibrating feeders, or screws may be used to meter coal into the coking system. |

| Monitoring & sensors | Level sensors, flow sensors, temperature sensors to detect surges, blockages or hotspots. |

The coal bunker acts as the buffer, smoothing upstream changes and protecting the downstream coking process from feed disturbance.

Technical Specifications of Our Coking Equipment

Below is a detailed presentation of our coking equipment’s parameters and features. We break down key modules to show professional depth.

A. Core Equipment Modules & Features

| Module / Component | Parameter / Spec | Typical Value / Range | Purpose / Notes |

|---|---|---|---|

| Number of ovens / chambers | n | 20 – 100 (can custom) | Determines parallel throughput |

| Chamber dimensions | Width × Height × Depth | e.g. 0.6 m × 2.5 m × 15 m | Tailored to capacity & coal type |

| Heating temperature range | 900 °C to 1,300 °C | Depends on coal type | Pyrolysis / carbonization zone |

| Heating rate | °C/hour | 100 – 300 °C/h | Controls volatile release kinetics |

| Coking cycle time | h | 15 – 30 hours | Time for full carbonization + cooling |

| Cooling method | Water quench / inert gas / dry quenching | Customizable | Affects coke quality & emissions |

| Sealing system | Bell seal, hydraulic / mechanical | — | Prevent oxygen ingress, gas leakage |

| Gas recovery & purification | Volume (Nm³/h), sulfur removal (ppm) | e.g. 5,000 Nm³/h, ≤ 100 ppm SO₂ | Meet environmental norms |

| Ash content tolerance | % | ≤ 10 % (depending on coal) | Coal feed requirement |

| Feed coal size | mm | < 50 mm typically | To ensure uniform heating |

| Throughput per chamber | ton/day | e.g. 200–500 t/d | Varies with design |

| Material & lining | Refractory brick, high-grade alloy | — | Withstand high temperature & corrosion |

| Control system | PLC / DCS with SCADA | — | Automation, alarms, data logging |

| Maintenance interval | months | e.g. 12–24 months | For refractory, seals, mechanical parts |

B. Example: Sample Specification for a Mid-Scale Unit

Here is an example configuration:

| Parameter | Value |

|---|---|

| Total number of chambers | 30 |

| Chamber size (W × H × D) | 0.6 m × 2.5 m × 12 m |

| Cycle time | 24 hours |

| Heating temperature | up to 1,200 °C |

| Throughput per chamber | ~ 300 t/day |

| Total throughput | ~ 9,000 t/day |

| Cooling method | Dry quenching with inert gas |

| Gas recovery | 8,000 Nm³/h, ≤ 80 ppm SO₂ |

| Control system | DCS with remote monitoring |

| Refractory life expectancy | > 2 years under design conditions |

| Coal feed size | 0 – 40 mm |

| Max ash tolerance | 8 % |

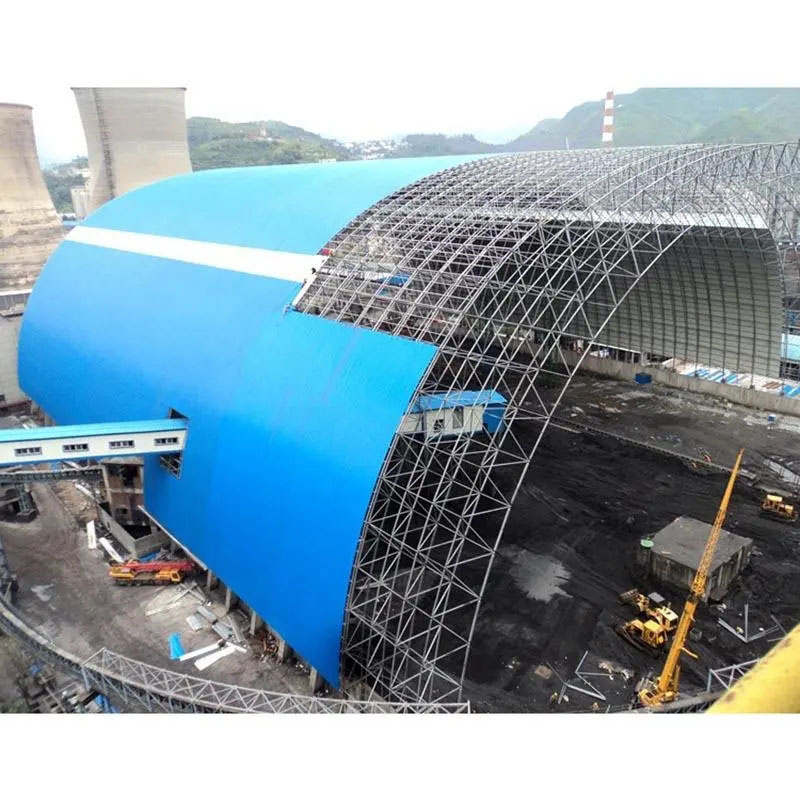

C. Integration & Supporting Systems

-

Coal preparation & crushing: Ensure feed coal is in acceptable size.

-

Gas handling & purification: Systems for tar removal, sulfur scrubbing, dust separation.

-

Heat recovery & reuse: Flue gas heat exchangers, steam generation systems.

-

Emission controls: Dust catchers, scrubbers, VOC abatement.

-

Instrumentation & monitoring: Temperature, pressure, gas composition, flow, level sensors.

-

Safety systems: Overpressure relief, inert gas purging, emergency shutdown.

These specifications are customizable — we design per site, coal type, environmental limits, and desired throughput.

Common Questions & Answers about Coking Equipment (FAQ)

Q: What coal properties are critical for good coking performance?

A: The key coal properties include volatile content, ash content, sulfur content, moisture, and size distribution. Low ash, moderate volatile matter, low sulfur, and controlled size are best. These determine coke quality, emissions, and thermal dynamics.

Q: How long is the typical operational lifetime of a coking equipment system?

A: With proper maintenance, refractory renewal, parts replacement, and operation within design parameters, a coking system can serve reliably for 20+ years. Key wear parts (seals, refractory) may require periodic servicing.

Q: How is emission control handled in modern coking plants?

A: Emissions are controlled via gas recovery (capture of volatile gases), tar / ammonia / sulfur scrubbing, dust filters, and inert gas sealing to prevent oxygen ingress. Compliance with local environmental regulations is integrated in the design.

Recent Industry News in Question Form & Summary / Contact

What recent trends or news are influencing the coking equipment sector?

-

Why are steel and energy demands pushing coking plant upgrades?

As global demand for steel and energy intensifies, operators are seeking more efficient, lower-emission coking systems to reduce cost and comply with stricter environmental standards. -

How is carbon regulation affecting coking plants?

Emission caps and carbon pricing in many jurisdictions force coking plant operators to invest in carbon capture, VOC control, and energy recovery systems. -

What innovations are emerging in coking equipment design?

New materials (high-temperature ceramics, advanced alloys), improved control systems (AI/ML predictive maintenance), and modular units for flexible scale are gaining traction.

These news items, framed as questions, align with commonly searched informational queries in industrial equipment and manufacturing sectors.

Our coking equipment offerings are engineered to meet rigorous industrial demands, blending high throughput, emissions control, long lifespan, and flexible customization. Whether your focus is metallurgical coke production, chemical gas recovery, or integrated power generation, we deliver systems built for performance.

We proudly deliver under our Lano, built on decades of engineering and industry trust. For system design, pricing, consultation, or site integration, contact us — we’ll help you design the optimal coking solution tailored to your needs.